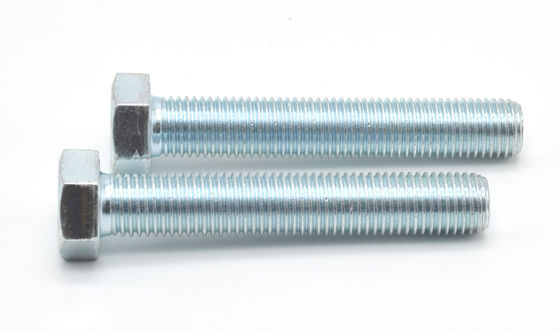

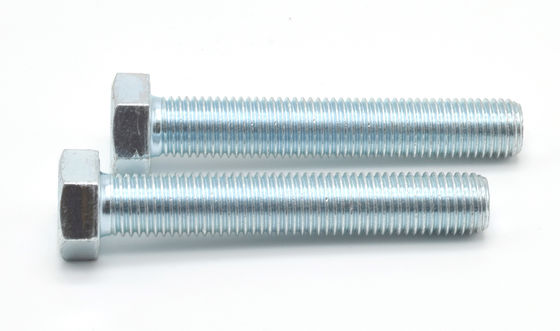

DIN933 ISO4017 EN24017 Hexagon Head Bolts Full Thread Carbon Steel / Alloy Steel

Contact me for free samples and coupons.

Whatsapp:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

If you have any concern, we provide 24-hour online help.

x| Name | Hexagon Head Bolts - Full Thread | Standard | GB/DIN/ASME/EN/ISO&etc. |

|---|---|---|---|

| Materials | Alloy Steel 40Cr/Carbon Steel 35K | Surface Treatment | Zinc Plated |

| Grade | 8.8/10.9 | Color | Blue-White |

| Surface | Galvanized | Length | 8mm-240mm/According Your Requirements |

| Size | M4-M30/According Your Requirements | ||

| Highlight | DIN933 Hexagon Head Bolts,Full Thread DIN933 Bolt,Alloy Steel Full Thread Bolts |

||

DIN933 ISO4017 EN24017 Hexagon Head Bolts Full Thread Blue-White Zinc Coating Carbon Steel/Alloy Steel Class 8.8 10.9

Advantages

- Excellent Corrosion Resistance: The blue-white zinc coating effectively prevents corrosion of the bolts in acidic, alkaline, and oxidizing environments, significantly enhancing their corrosion resistance.

- Uniform and Smooth Coating: The blue-white zinc coating process produces a uniform and smooth coating on the bolt surface, making the bolts visually appealing and reducing the risk of corrosion due to uneven coating.

- Environmental Friendliness: The blue-white zinc coating process often utilizes chromium-free, environmentally friendly anti-corrosion technology, using simple raw materials and posing less pollution to the environment.

Characteristics

- High Hardness: The blue-white zinc coating increases the bolt's hardness, enhancing its mechanical properties and durability.

- Non-Peeling: The blue-white zinc coating adheres tightly to the bolt's base material, preventing peeling and ensuring stability during use.

- Attractive Appearance: The blue-white zinc coating features a unique bluish-white hue, making the bolts visually appealing and suitable for applications requiring aesthetic considerations.

Applications

- Construction Industry: In the construction industry, DIN 931-1 bolts with a blue-white zinc coating are commonly used for connecting and fixing various components, such as steel structures and bridges. Their excellent corrosion resistance and mechanical properties ensure the stability and safety of buildings.

- Machinery and Automotive Industry: In the machinery and automotive industries, these bolts are widely applied in the assembly of various machines and equipment. Their high hardness and good corrosion resistance ensure the smooth operation and durability of machines and equipment.

- Power and Telecommunications Industry: In power and telecommunications infrastructure, these bolts are used for fixing and supporting cables, lines, and towers. Their corrosion resistance and stability ensure the smooth operation of power and telecommunications systems.

In summary, DIN 931-1 bolts with a blue-white zinc coating, owing to their excellent corrosion resistance, mechanical properties, and environmental friendliness, find widespread applications in various industries.

![]()

| Nominal Diameter | M2 | M2.5 | M3 | (M3.5) | M4 | M5 | M6 | (M7) | M8 | M10 | M12 | (M14) | M16 | |

| P | Pitch | 0.4 | 0.45 | 0.5 | 0.6 | 0.7 | 0.8 | 1 | 1 | 1.25 | 1.5 | 1.75 | 2 | 2 |

| k | Nominal Size | 1.4 | 1.7 | 2 | 2.4 | 2.8 | 3.5 | 4 | 4.8 | 5.3 | 6.4 | 7.5 | 8.8 | 10 |

| Grade A min | 1.28 | 1.58 | 1.88 | 2.28 | 2.68 | 3.35 | 3.85 | 4.65 | 5.15 | 6.22 | 7.32 | 8.62 | 9.82 | |

| Grade A max | 1.52 | 1.82 | 2.12 | 2.52 | 2.92 | 3.65 | 4.15 | 4.95 | 5.45 | 6.56 | 7.68 | 8.98 | 10.18 | |

| Grade B min | / | / | / | / | 2.6 | 3.26 | 3.76 | 4.56 | 5.06 | 6.11 | 7.21 | 8.51 | 9.71 | |

| Grade B max | / | / | / | / | 3 | 3.74 | 4.24 | 5.04 | 5.54 | 6.69 | 7.79 | 9.09 | 10.29 | |

| s | max=nominal size | 4 | 5 | 5.5 | 6 | 7 | 8 | 10 | 11 | 13 | 17 | 19 | 22 | 24 |

| Grade A min | 3.82 | 4.82 | 5.32 | 5.82 | 6.78 | 7.78 | 9.78 | 10.73 | 12.73 | 16.73 | 18.67 | 21.67 | 23.67 | |

| Grade B min | / | / | / | / | 6.64 | 7.64 | 9.64 | 10.57 | 12.57 | 16.57 | 18.48 | 21.16 | 23.16 | |

| e | Grade A min | 4.32 | 5.45 | 6.01 | 6.58 | 7.66 | 8.79 | 11.05 | 12.12 | 14.38 | 18.9 | 21.1 | 24.49 | 26.75 |

| Grade B min | / | / | / | / | 7.5 | 8.63 | 10.89 | 11.94 | 14.2 | 18.72 | 20.88 | 23.91 | 26.17 | |

| Nominal Diameter | (M18) | M20 | (M22) | M24 | (M27) | M30 | (M33) | M36 | (M39) | M42 | (M45) | M48 | (M52) | |

| P | Pitch | 2.5 | 2.5 | 2.5 | 3 | 3 | 3.5 | 3.5 | 4 | 4 | 4.5 | 4.5 | 5 | 5 |

| k | Nominal Size | 11.5 | 12.5 | 14 | 15 | 17 | 18.7 | 21 | 22.5 | 25 | 26 | 28 | 30 | 33 |

| Grade A min | 11.28 | 12.28 | 13.78 | 14.78 | / | / | / | / | / | / | / | / | / | |

| Grade A max | 11.72 | 12.72 | 14.22 | 15.22 | / | / | / | / | / | / | / | / | / | |

| Grade B min | 11.15 | 12.15 | 13.65 | 14.65 | 16.65 | 18.28 | 20.58 | 22.08 | 24.58 | 25.58 | 27.58 | 29.58 | 32.5 | |

| Grade B max | 11.85 | 12.85 | 14.35 | 15.35 | 17.35 | 19.12 | 21.42 | 22.92 | 25.42 | 26.42 | 28.42 | 30.42 | 33.5 | |

| s | max=nominal size | 27 | 30 | 32 | 36 | 41 | 46 | 50 | 55 | 60 | 65 | 70 | 75 | 80 |

| Grade A min | 26.67 | 29.67 | 31.61 | 35.38 | / | / | / | / | / | / | / | / | / | |

| Grade B min | 26.15 | 29.16 | 31 | 35 | 40 | 45 | 49 | 53.8 | 58.8 | 63.1 | 68.1 | 73.1 | 78.1 | |

| e | Grade A min | 30.14 | 33.53 | 35.72 | 39.98 | / | / | / | / | / | / | / | / | / |

| Grade B min | 29.56 | 32.95 | 35.03 | 39.55 | 45.2 | 50.85 | 55.37 | 60.79 | 66.44 | 71.3 | 76.95 | 82.6 | 88.25 | |