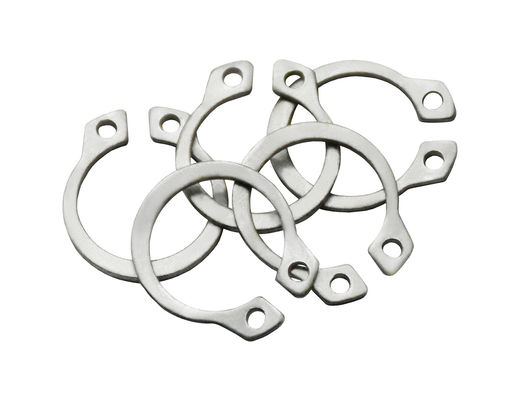

DIN 471 SUS304 / 65Mn Parkerizing Retaining Rings Normal Type For Shafts

Contact me for free samples and coupons.

Whatsapp:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

If you have any concern, we provide 24-hour online help.

x| Name | Retaining Rings For Shafts - Normal Type | Standard | GB/DIN/ASME/EN/ISO&etc. |

|---|---|---|---|

| Type | Retaining Rings | Finish | Black ,Dacromet,Black Oxide,Plain,Parkerising |

| Package | PE Bag+Label+Carton | Surface Treatment | Dacromet,Black,Polishing,Parkerising |

| Size | Φ17-Φ270 | Material | SUS304 65Mn |

| Highlight | Shafts Retaining Rings,Parkerizing Retaining Rings,Din 471 Retaining Ring |

||

DIN471 SUS304/65Mn Black/Parkerising/Dacromet/Plain/Galvanization Retaining Rings For Shafts - Normal Type Φ17-Φ270

![]()

| Nominal Diameter | 8 | 9 | 10 | 11 | 12 | 13 | 14 | |

| d ① | ||||||||

| s | max | 0.8 | 0.8 | 1 | 1 | 1 | 1 | 1 |

| min | 0.75 | 0.75 | 0.94 | 0.94 | 0.94 | 0.94 | 0.94 | |

| dc | max | 9.06 | 10.16 | 11.16 | 12.16 | 13.36 | 14.46 | 15.46 |

| min | 8.6 | 9.7 | 10.7 | 11.7 | 12.9 | 14 | 15 | |

| a | max | 2.4 | 2.5 | 3.2 | 3.3 | 3.4 | 3.6 | 3.7 |

| b | ≈ | 1.1 | 1.3 | 1.4 | 1.5 | 1.7 | 1.8 | 1.9 |

| d1 | min | 1 | 1 | 1.2 | 1.2 | 1.5 | 1.5 | 1.7 |

| d2 | 3 | 3.7 | 3.3 | 4.1 | 4.9 | 5.4 | 6.2 | |

| per 1000 units ≈ kg | 0.14 | 0.15 | 0.18 | 0.31 | 0.37 | 0.42 | 0.52 | |

| Nominal Diameter | 15 | 16 | 17 | 18 | 19 | 20 | 21 | |

| d ① | ||||||||

| s | max | 1 | 1 | 1 | 1 | 1 | 1 | 1 |

| min | 0.94 | 0.94 | 0.94 | 0.94 | 0.94 | 0.94 | 0.94 | |

| dc | max | 16.56 | 17.66 | 18.72 | 19.92 | 20.92 | 21.92 | 22.92 |

| min | 16.1 | 17.2 | 18.17 | 19.37 | 20.37 | 21.37 | 22.37 | |

| a | max | 3.7 | 3.8 | 3.9 | 4.1 | 4.1 | 4.2 | 4.2 |

| b | ≈ | 2 | 2 | 2.1 | 2.2 | 2.2 | 2.3 | 2.4 |

| d1 | min | 1.7 | 1.7 | 1.7 | 2 | 2 | 2 | 2 |

| d2 | 7.2 | 8 | 8.8 | 9.4 | 10.4 | 11.2 | 12.2 | |

| per 1000 units ≈ kg | 0.56 | 0.6 | 0.65 | 0.74 | 0.83 | 0.9 | 1 | |

| Nominal Diameter | 22 | 24 | 25 | 26 | 28 | 30 | 31 | |

| d ① | ||||||||

| s | max | 1 | 1.2 | 1.2 | 1.2 | 1.2 | 1.2 | 1.2 |

| min | 0.94 | 1.14 | 1.14 | 1.14 | 1.14 | 1.14 | 1.14 | |

| dc | max | 23.92 | 26.32 | 27.32 | 28.32 | 30.6 | 32.6 | 33.9 |

| min | 23.37 | 25.69 | 26.69 | 27.69 | 29.85 | 31.85 | 33.15 | |

| a | max | 4.2 | 4.4 | 4.5 | 4.7 | 4.8 | 4.8 | 5.2 |

| b | ≈ | 2.5 | 2.6 | 2.7 | 2.8 | 2.9 | 3 | 3.2 |

| d1 | min | 2 | 2 | 2 | 2 | 2 | 2 | 2.5 |

| d2 | 13.2 | 14.8 | 15.5 | 16.1 | 17.9 | 19.9 | 20 | |

| per 1000 units ≈ kg | 1.1 | 1.42 | 1.5 | 1.6 | 1.8 | 2.06 | 2.1 | |

| Nominal Diameter | 32 | 34 | 35 | 36 | 37 | 38 | 40 | |

| d ① | ||||||||

| s | max | 1.2 | 1.5 | 1.5 | 1.5 | 1.5 | 1.5 | 1.75 |

| min | 1.14 | 1.44 | 1.44 | 1.44 | 1.44 | 1.44 | 1.69 | |

| dc | max | 34.9 | 37 | 38.3 | 39.3 | 40.3 | 41.3 | 44.4 |

| min | 34.15 | 36.25 | 37.55 | 38.55 | 39.55 | 40.55 | 43.11 | |

| a | max | 5.4 | 5.4 | 5.4 | 5.4 | 5.5 | 5.5 | 5.8 |

| b | ≈ | 3.2 | 3.3 | 3.4 | 3.5 | 3.6 | 3.7 | 3.9 |

| d1 | min | 2.5 | 2.5 | 2.5 | 2.5 | 2.5 | 2.5 | 2.5 |

| d2 | 20.6 | 22.6 | 23.6 | 24.6 | 25.4 | 26.4 | 27.8 | |

| per 1000 units ≈ kg | 2.21 | 3.2 | 3.54 | 3.7 | 3.74 | 3.9 | 4.7 | |

| Nominal Diameter | 42 | 45 | 47 | 48 | 50 | 52 | 55 | |

| d ① | ||||||||

| s | max | 1.75 | 1.75 | 1.75 | 1.75 | 2 | 2 | 2 |

| min | 1.69 | 1.69 | 1.69 | 1.69 | 1.93 | 1.93 | 1.93 | |

| dc | max | 46.4 | 49.4 | 51.6 | 52.6 | 55.3 | 57.3 | 60.3 |

| min | 45.11 | 48.11 | 50.04 | 51.04 | 53.74 | 55.74 | 58.74 | |

| a | max | 5.9 | 6.2 | 6.4 | 6.4 | 6.5 | 6.7 | 6.8 |

| b | ≈ | 4.1 | 4.3 | 4.4 | 4.5 | 4.6 | 4.7 | 5 |

| d1 | min | 2.5 | 2.5 | 2.5 | 2.5 | 2.5 | 2.5 | 2.5 |

| d2 | 29.6 | 32 | 33.5 | 34.5 | 36.3 | 37.9 | 40.7 | |

| per 1000 units ≈ kg | 5.4 | 6 | 6.1 | 6.7 | 7.3 | 8.2 | 8.3 | |

| Nominal Diameter | 56 | 58 | 60 | 62 | 63 | 65 | 68 | |

| d ① | ||||||||

| s | max | 2 | 2 | 2 | 2 | 2 | 2.5 | 2.5 |

| min | 1.93 | 1.93 | 1.93 | 1.93 | 1.93 | 2.43 | 2.43 | |

| dc | max | 61.3 | 63.3 | 65.3 | 67.3 | 68.3 | 70.3 | 73.6 |

| min | 59.74 | 61.74 | 63.74 | 65.74 | 66.74 | 68.74 | 72.04 | |

| a | max | 6.8 | 6.9 | 7.3 | 7.3 | 7.3 | 7.6 | 7.8 |

| b | ≈ | 5.1 | 5.2 | 5.4 | 5.5 | 5.6 | 5.8 | 6.1 |

| d1 | min | 2.5 | 2.5 | 2.5 | 2.5 | 2.5 | 3 | 3 |

| d2 | 41.7 | 43.5 | 44.7 | 46.7 | 47.7 | 49 | 51.6 | |

| per 1000 units ≈ kg | 8.7 | 10.5 | 11.1 | 11.2 | 12.4 | 14.3 | 16 | |

| Nominal Diameter | 70 | 72 | 75 | 78 | 80 | 82 | 85 | |

| d ① | ||||||||

| s | max | 2.5 | 2.5 | 2.5 | 2.5 | 2.5 | 2.5 | 3 |

| min | 2.43 | 2.43 | 2.43 | 2.43 | 2.43 | 2.43 | 2.92 | |

| dc | max | 75.6 | 77.6 | 80.6 | 83.8 | 86.8 | 88.8 | 91.8 |

| min | 74.04 | 76.04 | 79.04 | 81.96 | 84.96 | 86.96 | 89.96 | |

| a | max | 7.8 | 7.8 | 7.8 | 8.5 | 8.5 | 8.5 | 8.6 |

| b | ≈ | 6.2 | 6.4 | 6.6 | 6.8 | 7 | 7 | 7.2 |

| d1 | min | 3 | 3 | 3 | 3 | 3 | 3 | 3.5 |

| d2 | 53.6 | 55.6 | 58.6 | 60.1 | 62.1 | 64.1 | 66.9 | |

| per 1000 units ≈ kg | 16.5 | 18.1 | 18.8 | 20.4 | 22 | 24 | 25.3 | |

| Nominal Diameter | 88 | 90 | 92 | 95 | 98 | 100 | 102 | |

| d ① | ||||||||

| s | max | 3 | 3 | 3 | 3 | 3 | 3 | 4 |

| min | 2.92 | 2.92 | 2.92 | 2.92 | 2.92 | 2.92 | 3.9 | |

| dc | max | 94.8 | 96.8 | 98.8 | 101.8 | 104.8 | 106.8 | 109.3 |

| min | 92.96 | 94.96 | 96.96 | 99.96 | 102.96 | 104.96 | 107.46 | |

| a | max | 8.6 | 8.6 | 8.7 | 8.8 | 9 | 9.2 | 9.5 |

| b | ≈ | 7.4 | 7.6 | 7.8 | 8.1 | 8.3 | 8.4 | 8.5 |

| d1 | min | 3.5 | 3.5 | 3.5 | 3.5 | 3.5 | 3.5 | 3.5 |

| d2 | 69.9 | 71.9 | 73.7 | 76.5 | 79 | 80.6 | 82 | |

| per 1000 units ≈ kg | 28 | 31 | 32 | 35 | 37 | 38 | 55 | |

| Nominal Diameter | 105 | 108 | 110 | 112 | 115 | 120 | 125 | |

| d ① | ||||||||

| s | max | 4 | 4 | 4 | 4 | 4 | 4 | 4 |

| min | 3.9 | 3.9 | 3.9 | 3.9 | 3.9 | 3.9 | 3.9 | |

| dc | max | 113.3 | 116.3 | 118.3 | 120.3 | 123.5 | 128.5 | 133.5 |

| min | 111.46 | 114.46 | 116.46 | 118.46 | 121.37 | 126.37 | 131.37 | |

| a | max | 9.5 | 9.5 | 10.4 | 10.5 | 10.5 | 11 | 11 |

| b | ≈ | 8.7 | 8.9 | 9 | 9.1 | 9.3 | 9.7 | 10 |

| d1 | min | 3.5 | 3.5 | 3.5 | 3.5 | 3.5 | 3.5 | 4 |

| d2 | 85 | 88 | 88.2 | 90 | 93 | 96.9 | 101.9 | |

| per 1000 units ≈ kg | 56 | 60 | 64.5 | 72 | 74.5 | 77 | 79 | |

| Nominal Diameter | 130 | 135 | 140 | 145 | 150 | 155 | 160 | |

| d ① | ||||||||

| s | max | 4 | 4 | 4 | 4 | 4 | 4 | 4 |

| min | 3.9 | 3.9 | 3.9 | 3.9 | 3.9 | 3.9 | 3.9 | |

| dc | max | 138.5 | 143.5 | 148.5 | 153.5 | 159.5 | 165.5 | 170.5 |

| min | 136.37 | 141.37 | 146.37 | 151.37 | 157.37 | 163.37 | 168.37 | |

| a | max | 11 | 11.2 | 11.2 | 11.4 | 12 | 12 | 13 |

| b | ≈ | 10.2 | 10.5 | 10.7 | 10.9 | 11.2 | 11.4 | 11.6 |

| d1 | min | 4 | 4 | 4 | 4 | 4 | 4 | 4 |

| d2 | 106.9 | 111.5 | 116.5 | 121 | 124.8 | 129.8 | 132.7 | |

| per 1000 units ≈ kg | 82 | 84 | 87.5 | 93 | 105 | 107 | 110 | |

| Nominal Diameter | 165 | 170 | 175 | 180 | 185 | 190 | 195 | |

| d ① | ||||||||

| s | max | 4 | 4 | 4 | 4 | 4 | 4 | 4 |

| min | 3.9 | 3.9 | 3.9 | 3.9 | 3.9 | 3.9 | 3.9 | |

| dc | max | 176 | 181 | 186.2 | 191.2 | 196.2 | 201.2 | 206.2 |

| min | 173.87 | 178.87 | 183.78 | 188.78 | 193.78 | 198.78 | 203.78 | |

| a | max | 13 | 13.5 | 13.5 | 14.2 | 14.2 | 14.2 | 14.2 |

| b | ≈ | 11.8 | 12.2 | 12.7 | 13.2 | 13.7 | 13.8 | 13.8 |

| d1 | min | 4 | 4 | 4 | 4 | 4 | 4 | 4 |

| d2 | 137.7 | 141.6 | 146.6 | 150.2 | 155.2 | 160.2 | 165.2 | |

| per 1000 units ≈ kg | 125 | 140 | 150 | 165 | 170 | 175 | 183 | |

| Nominal Diameter | 200 | 210 | 220 | 230 | 240 | 250 | 260 | |

| d ① | ||||||||

| s | max | 4 | 5 | 5 | 5 | 5 | 5 | 5 |

| min | 3.9 | 4.88 | 4.88 | 4.88 | 4.88 | 4.88 | 4.88 | |

| dc | max | 211.2 | 223.7 | 233.7 | 243.7 | 254 | 264 | 277 |

| min | 208.78 | 221.28 | 231.28 | 241.28 | 251.19 | 261.19 | 274.19 | |

| a | max | 14.2 | 14.2 | 14.2 | 14.2 | 14.2 | 14.2 | 16.2 |

| b | ≈ | 14 | 14 | 14 | 14 | 14 | 14 | 16 |

| d1 | min | 4 | 4 | 4 | 4 | 4 | 4 | 5 |

| d2 | 170.2 | 180.2 | 190.2 | 200.2 | 210.2 | 220.2 | 226 | |

| per 1000 units ≈ kg | 195 | 270 | 315 | 330 | 345 | 360 | 375 | |

| Nominal Diameter | 270 | 280 | 290 | 300 | ||||

| d ① | ||||||||

| s | max | 5 | 5 | 5 | 5 | |||

| min | 4.88 | 4.88 | 4.88 | 4.88 | ||||

| dc | max | 287 | 297 | 307 | 317 | |||

| min | 284.19 | 294.19 | 304.19 | 314.19 | ||||

| a | max | 16.2 | 16.2 | 16.2 | 16.2 | |||

| b | ≈ | 16 | 16 | 16 | 16 | |||

| d1 | min | 5 | 5 | 5 | 5 | |||

| d2 | 236 | 246 | 256 | 266 | ||||

| per 1000 units ≈ kg | 388 | 400 | 415 | 435 | ||||

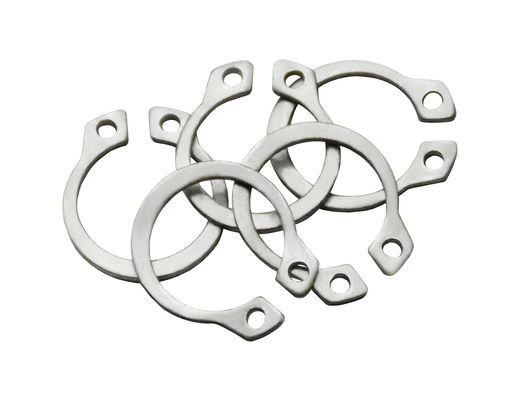

Retaining Rings for Bores - Normal Type are a common type of fastener in mechanical design, primarily used to secure parts on axles, preventing them from moving or falling off. Here is an introduction to the characteristics, advantages, and applicable scenarios of this type of retaining ring:

Characteristics:

- 1.Under the condition of complying with the standard DIN471, these retaining rings usually come in a variety of standard sizes, which can be adapted according to the shaft diameter and the size of the part that needs to be fixed.

- 2.The retaining ring is usually made of a circular metal sheet with a hole in the middle, which is simple, reliable and easy to install.

- 3.The retaining ring can be installed on the axle by pushing axially or tapping, without the need for special tools or equipment, making it easy to install.

- 4.Retaining rings can be made from various materials to accommodate a wide range of environmental requirements.

Advantages:

- 1. Installing retaining rings can effectively prevent parts from displacing or even falling off the axle, ensuring the safety and stability of the mechanical system.

- 2. Due to the simplicity of their structure, retaining rings have relatively low manufacturing costs, making them suitable for large-scale production.

- 3. As retaining rings are manufactured in accordance with the DIN471 standard, they are able to adapt to various axle diameters and part sizes, demonstrating high adaptability and strong versatility.

- 4. Due to the simplicity of the retaining ring's structure, both its installation and removal processes are relatively straightforward, which facilitates the maintenance of equipment and the replacement of parts.

Applicable Scenarios:

- Transmission Parts on Axles: In transmission systems, such as gears and pulley wheels, retaining rings can be used to fix parts onto axles.

- Bearing Fixation: In some applications, it is necessary to ensure the stability of bearings on axles, where retaining rings come into play.

- Positioning Elements: Retaining rings can also serve as positioning elements, ensuring accurate relative positions of other parts on axles.

- Frequent Part Replacement Scenarios: Due to their ease of installation and removal, retaining rings are particularly suitable for scenarios requiring frequent part replacements, such as in test equipment and testing benches.

In summary, retaining rings for bores - normal type are fasteners with simple structures, convenient installation, low costs, and strong adaptability, widely applied in various mechanical systems.